|

Design S Series

For model

MH-94S/104/124S and MH-124SD

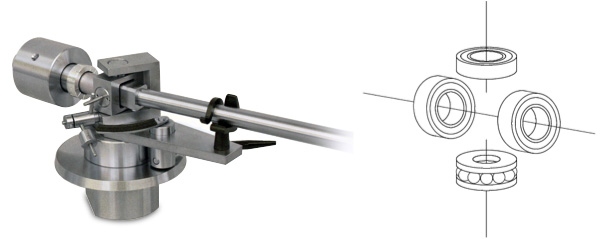

The material of the main body is made of

hard stainless steel. The process of

machining has been extremely difficult,

but as a result, but we are proud to say

that the sound quality has reached an

unparalleled level. If the fulcrum,

which is essential for sound quality, is

a weak structure, it will reverberate

and directly impact the overall sound

quality. In this machine, the four large

bearings are firmly supported,

preventing resonance and shake, and

enhancing tracing ability.

In

particular, the lower bearing in the

vertical axis uses a high-precision

thrust bearing, giving a strut structure

which allows heavy arms to move with

high sensitivity, greatly enhancing the

tracking capability.

At the most

important section of the arm tube with

regards to impact on sound quality,

vibration is controlled firstly with a

layer of carbon fibre on the inside of

the arm, followed by a layer of poly

fibre on the inside of that. Next, the

wire that transmits the electric signal

is wrapped in silk thread using low

resistance silver wire, and around all

of this is the poly fibre, doubly

ensuring that it is vibration-proof.

(for model SD)

The points where each part joins another

are designed to be in tight surface

contact to avoid using adhesive as much

as possible. In particular, the assembly

of the bearings requires meticulous

sensitivity.

We took pains to ensure that the

curvature of the arm did not exert any

additional force. This is easier to

understand if you imagine how an extra

twisting force is applied by your hand

when you manipulate an L-shaped rod

rather than a straight one. On top of

that, we placed “vibration absorbing

structures” in the most suitable place,

thereby effectively damping the

resonance.

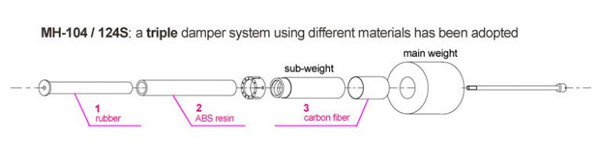

For the weight section we use different

damper materials in 1, 2, 3 and 4 (for

model SD), and these are constructed to

absorb vibration over a wide area. The

rubber material in 1 is firmly held in

place by long screws, thus eliminating

anxiety that it will become slack as it

ages.

Heavy tungsten is embedded in the

stainless steel material on the main

weight so that the centre of gravity is

closer to the fulcrum, and the stainless

steel material and tungsten are closely

bound with rubber material, which also

absorbs vibration. (for model SD)

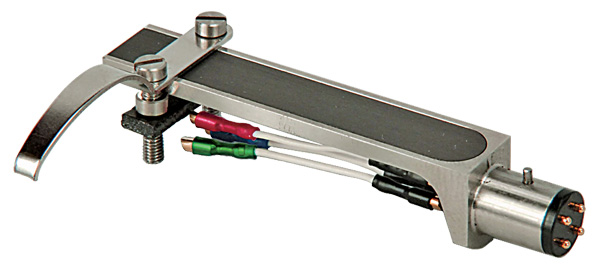

By making the

headshell into a single structure

through the scraping process, we were

able to greatly reduce vibration loss.

Moreover, by trimming away unnecessary

material as much as possible, we have

devised a weight reduction similar to

that of aluminium (although the material

is actually stainless steel), resulting

in an extremely light structure that can

firmly support the entire cartridge.

Rubber in the S Model and carbon in the

SD Model both absorb unnecessary signals

in the upper part of the structure.

Because this slim design (just 10 mm in

width, that can be supported near the

very centre of the cartridge), can be

connected directly to the centre point,

the vibration loss is reduced and the

sound quality is further improved.

|